Switching to CMYK Inks for the Secondary Packaging Printing of Ethical Pharmaceuticals to Reduce Environmental Impact

- Takeda will switch from special color inks to CMYK inks for printing secondary packaging (outer packaging) of its pharmaceuticals in Japan in order to reduce environmental impact.

- This is the first milestone under Takeda’s Global Artwork initiatives that aims to reduce environmental impact through artwork management on a global basis.

- The goal is to switch to CMYK inks for the secondary packaging of all our products manufactured in Japan by 2026. The other regions are going to follow over time.

- Takeda is also looking into the possibility of implementing digital printing in the future, while sharing our progress and findings with other pharmaceutical businesses in Japan and encouraging their involvement in this initiative.

OSAKA, Japan, January 25, 2024 - Takeda (TSE: 4502/NYSE: TAK) will switch its offset printing from special color inks to CMYK inks for printing secondary packaging (outer packaging) for its products as part of the company’s efforts to reduce its environmental impact. This is the first achievement under Takeda’s Global Artwork initiatives, which aims to reduce environmental impact through artwork management*1 on a global basis.

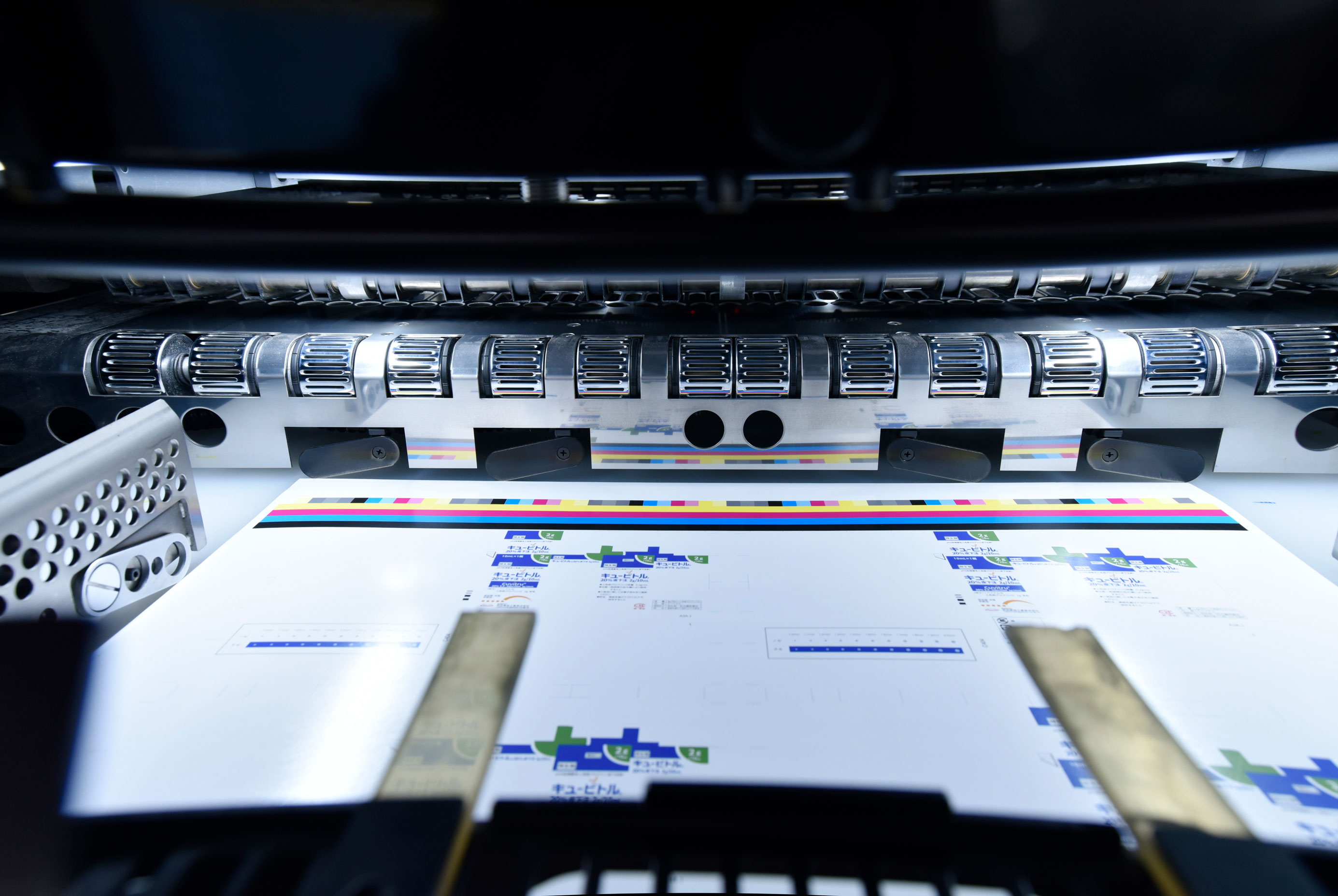

Takeda became an early adopter in the Japanese pharmaceutical industry by implementing this change. Specifically, the company is transitioning to CMYK printing for the secondary packaging of Cuvitru®. This product, which received marketing approval in Japan in September 2023 as the first subcutaneous immunoglobulin plasma therapy from Takeda, was recently launched. This switch is expected to reduce waste of unused ink in the supplier’s printing process as well as the amount of solvents necessary to clean the printing machine and the amount of waste generated during changeover between different products. In addition to reducing environmental impact, the switch is expected to result in cost savings.

When printing with special color inks—the standard for secondary packaging in Japan’s ethical pharmaceutical business—multiple inks are blended to create specific colors. In CMYK printing, a diverse range of colors is achieved through the combination of four colors: Cyan (blue), Magenta (red), Yellow, and Key Plate (black). This allows for a reduction in the variety and quantity of inks used compared to specialized ink printing methods. Furthermore, the printing machine does not need to be cleaned when switching between products printed using the CMYK process which is a continuous process not needing changeovers. Takeda is working towards a detailed life cycle assessment*2 of the printing processes to collect further data about the reduction of the environmental impact.

Takeda intends to switch to CMYK inks for the secondary packaging of all its products, new or existing, manufactured in Japan by 2026. The company is also looking into the possibility of moving away from offset printing and implementing digital printing in the future. In digital printing, the elimination of printing plates results in a reduction of water and solvent usage. Additionally, the absence of plate disposal contributes to a decreased environmental impact. Lastly, to reduce the environmental impact further still through economies of scale, Takeda will share the progress and learnings with other pharmaceutical companies and encourage them to join this initiative.

Greg Timmons, Takeda’s Head of Global Manufacturing & Supply - Japan, said, “As part of our corporate philosophy, we are committed to delivering a stable supply of high-quality medicines to patients while reducing our environmental impact on the planet. This program is one of our efforts to meet that goal. We will continue to proactively lead efforts in environmental sustainability within the pharmaceutical industry.”

Koji Nonomura, Head of Region Japan Artwork Coordination, Japan Regional Launch Excellence & Product Lifecycle Management, who led this initiative, said, “Moving forward, in order to further minimize the environmental impact through economies of scale, we will actively share progress and achievements with other pharmaceutical companies, encouraging their active participation in this initiative.”

*1 Designing, editing, and managing the printing and display of secondary packaging materials for pharmaceuticals, including outer packaging, user manuals, labels, and related items.

*2 A methodology for evaluating the extent to which environmental impact is reduced at each stage, from the extraction of raw materials through manufacturing, distribution, consumption, disposal to recycle over the entire life cycle of a product.

About Takeda

Takeda is focused on creating better health for people and a brighter future for the world. We aim to discover and deliver life-transforming treatments in our core therapeutic and business areas, including gastrointestinal and inflammation, rare diseases, plasma-derived therapies, oncology, neuroscience and vaccines. Together with our partners, we aim to improve the patient experience and advance a new frontier of treatment options through our dynamic and diverse pipeline. As a leading values-based, R\&D-driven biopharmaceutical company headquartered in Japan, we are guided by our commitment to patients, our people and the planet. Our employees in approximately 80 countries and regions are driven by our purpose and are grounded in the values that have defined us for more than two centuries. For more information, visit https://www.takeda.com.

Inquiries from the press:

Kumi Iiyama

Global Manufacturing & Supply Communications

Takeda Pharmaceutical Co., Ltd.

[email protected]

080-5789-7742