Our Stories Gallery | Takeda Pharmaceuticals

How digitalization enables sustainable manufacturing

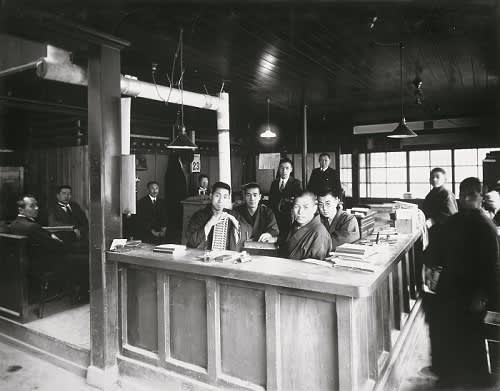

More than two centuries. Countless innovations. One vision.

From a single stall in an Osaka market to a global biopharmaceutical leader, we’ve always maintained a single set of values to guide our commitment to patients, our people and the planet.

And that has given us incredible stories to tell.

Setting sail – Pioneering sustainable transport of medicines by sea

November 14, 2025

Mentorship as multiplier: How mentorship strengthens communities

November 9, 2025

Climate-resilient health care: Our 2025 global CSR programs

September 24, 2025

The challenge of investigating the orexin pathway in narcolepsy type 1

September 19, 2025

Ito’s recipe for resilience with IBD

May 16, 2025

How we ‘level the playing field’ for small suppliers

April 28, 2025

From lost art to a lasting connection

April 17, 2025

Easing dietary challenges for IBD patients in Japan

April 17, 2025

Cultivating circular agriculture with a zoo in Japan

March 26, 2025

IBD patients embrace the everyday in European campaign

February 20, 2025

A first-of-its-kind collaboration to tackle health care emissions

February 10, 2025

Addressing the impact of climate change on child health

February 6, 2025

Understanding the root cause of inflammatory diseases

January 27, 2025

Small fish, big mission to protect biodiversity in Japan

January 23, 2025

Our approach to business development: Trust, agility, creativity

January 11, 2025

The impact of dengue: Two doctors’ perspectives

January 9, 2025

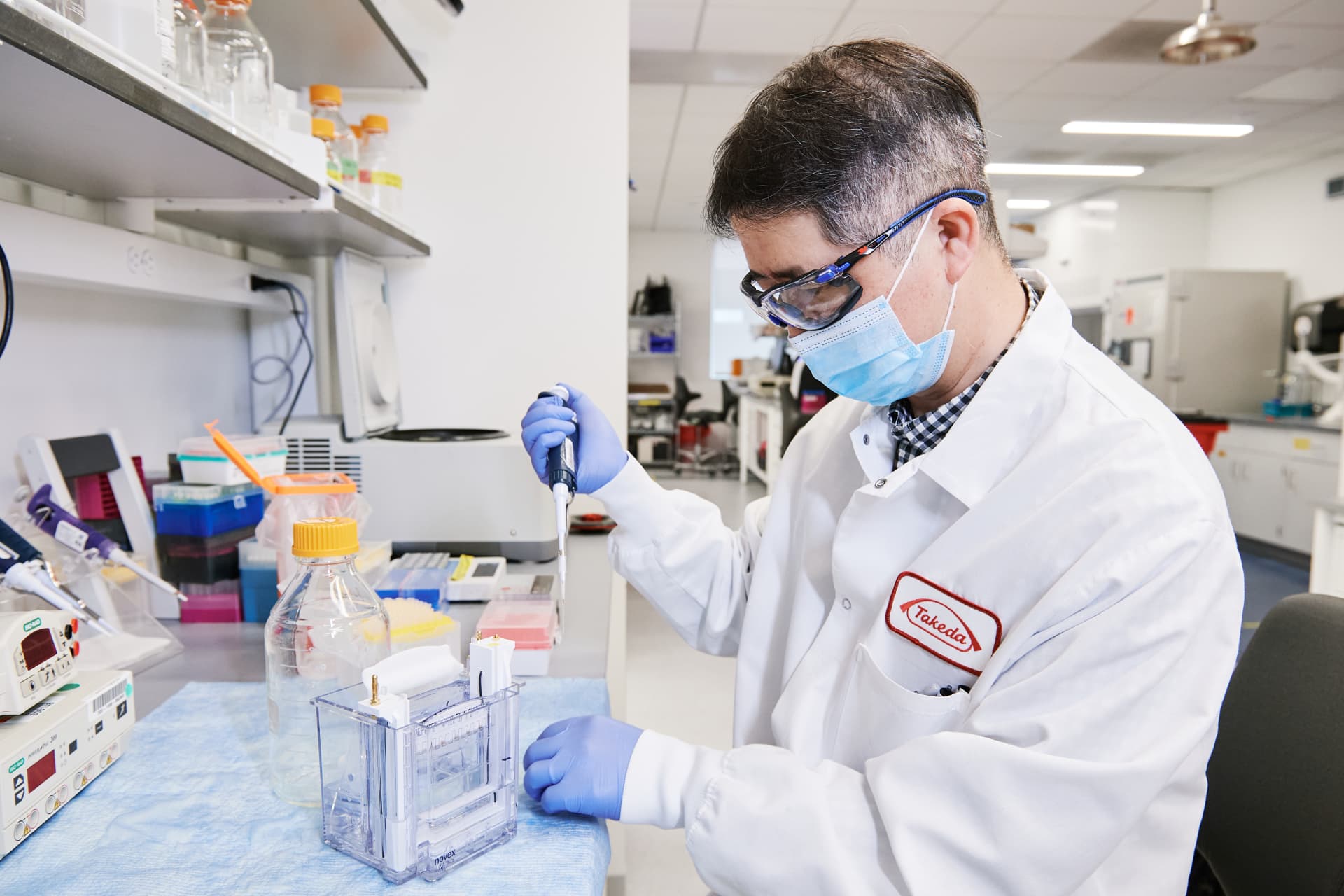

Driving innovation for narcolepsy type 1

December 19, 2024

Aiming to enhance regulatory submissions with GenAI

December 12, 2024

Joining forces to develop a multidisciplinary care model in GI

December 5, 2024

Innovative care navigators boost maternal health in India

December 5, 2024

Innovating to address neglected tropical diseases (NTDs)

November 14, 2024

Living with Psoriatic Disease: Stories of Resilience

October 25, 2024

Can wearable technology help in sleep disorder diagnosis?

October 17, 2024

Vaccine Business Unit leader's path began in dengue ward

October 17, 2024

In psoriatic arthritis, connections matter

October 9, 2024

From the heart: Meet our 2024 global CSR partners

September 19, 2024

Zambia’s first family medicine program overcomes the odds

September 19, 2024

Women, girls and health in the face of climate challenges

September 19, 2024

A new mother faces the challenge of the rare disease cTTP

September 12, 2024

Can Smart Technology help transform clinical trials?

September 12, 2024

The true burden of celiac disease: Bill’s journey

September 10, 2024

Preserving the 1,500-year-old hollyhock festival in Japan

September 4, 2024

Community Health Workers: Applying global lessons learned

August 29, 2024

How a conversation led to a new AI assistant

July 18, 2024

Community engagement to diversify clinical trials

June 25, 2024

![Picture of (Left to right): Junjing (Jane) Lin [Takeda], Hamaad Adam [MIT], Jianchang Lin [Takeda]](https://assets-dam.takeda.com/image/upload/c_lfill,w_1920/q_auto:eco/f_auto/v1/Global/Our-Stories/MIT-Takeda%20Program%20uses%20AI%20to%20unlock%20innovation/0019_MIT_Takeda_celebration_2024_019)

MIT-Takeda Program uses AI to unlock innovation

June 20, 2024

The burden of dengue and hope amidst hardship

June 13, 2024

Living with narcolepsy: Kelsey's story

June 12, 2024

Innovation in access reaches new heights

May 2, 2024

Haunted by dengue, she fights social inequities

April 29, 2024

Engaging patients at the Healthcare Café in Japan

April 18, 2024

Health inequity in rare disease: The long journey to diagnosis

February 29, 2024

Run Takeda Run

February 7, 2024

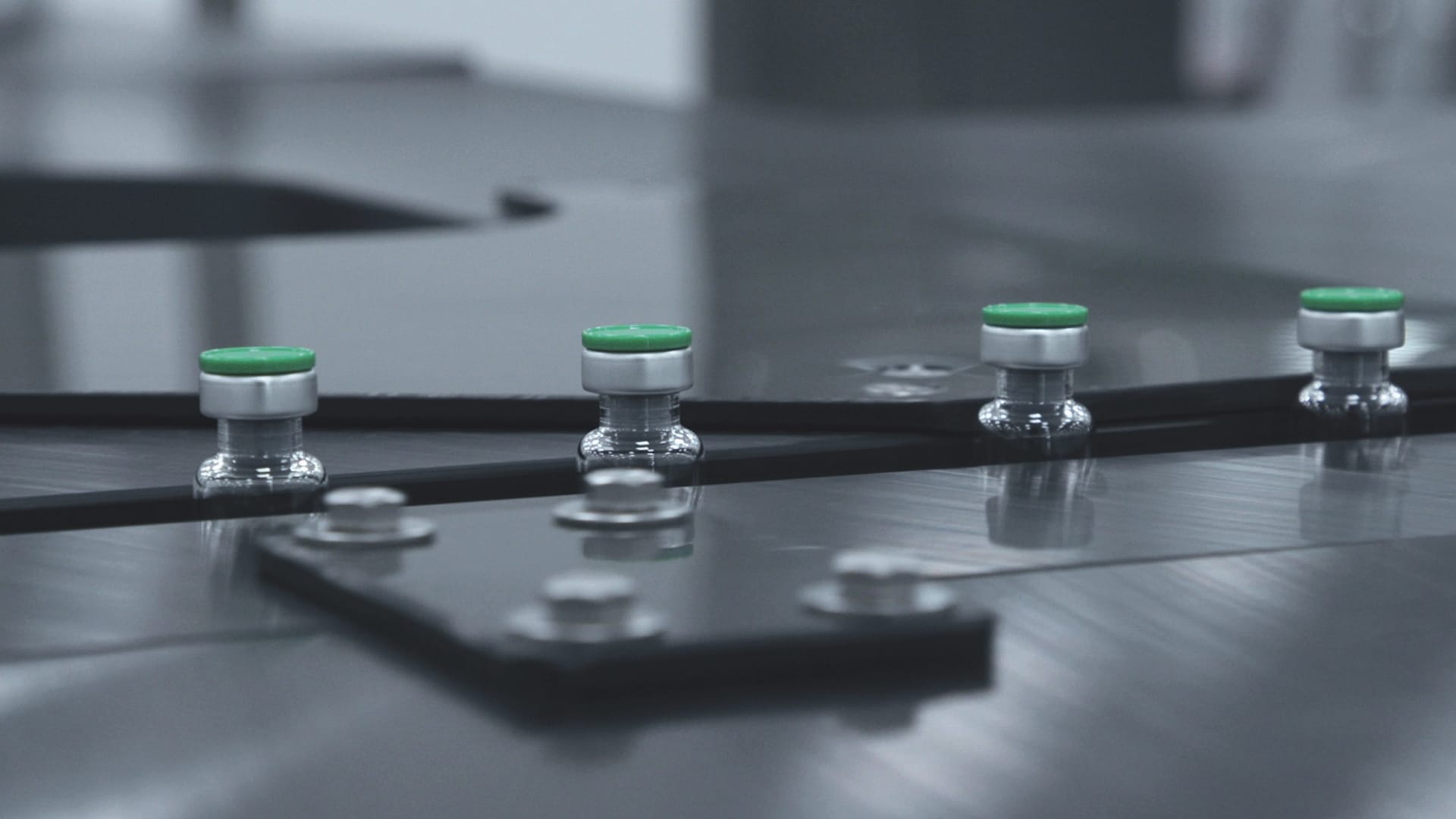

Pride in producing plasma-derived therapies

January 11, 2024

Offering IBD patients special recipes from Hyatt chefs

December 19, 2023

An unusual mural honors rare disease patients

December 14, 2023

Long-term partnership yields positive results for refugees

November 30, 2023

What drives our dengue researchers? Seeing the disease up close

November 2, 2023

Doing more in psoriasis starts with listening and learning

October 11, 2023

Hear from our 2023 Global CSR partners

October 4, 2023

Spotlighting research and innovation for patients with TTP

September 12, 2023

This new building produces more energy than it uses

September 7, 2023

Integrity in the aftermath of a historic earthquake in Japan

August 31, 2023

R&D colleagues share their stories

August 7, 2023

A father's experience with dengue

June 15, 2023

Takeda’s focus on health equity: Rare Disease Day 2023

February 25, 2023

Pursuing life-transforming science

January 17, 2023

A digital transformation to make a global impact

November 9, 2022

Harnessing science to push the boundaries of what’s possible

September 21, 2022

Integrating data sciences into clinical development

September 19, 2022

Training health workers to reach remote communities

March 9, 2022

Evi found a team who makes her feel heard

February 10, 2022

Innovation is key to sustaining our business

December 15, 2021

Improving the health of ethnic minority women and newborns in Asia

November 17, 2021

Elvis brought a global vision to his home office

June 12, 2021

For Aki, "Takeda-ism" is a family affair

June 9, 2021

Universal Health Coverage and the power of people: UNGA side event

November 21, 2019

Transforming global child health research with the LSHTM

August 8, 2019

Shared knowledge for a better life for all

November 9, 2018

Shonan Health Innovation Park ("Shonan iPark")

April 18, 2018

Health care for all

January 15, 2017